Introduction to the assembly line labeling head

Dear Customer: Hello,According to your companyProducts andLabeling requirements, recommended useHuashenda equipment assembly line labeling machine can helpYour companyimproveProduction efficiency, the following equipmentBasicsmaterial,respectPlease refer to.

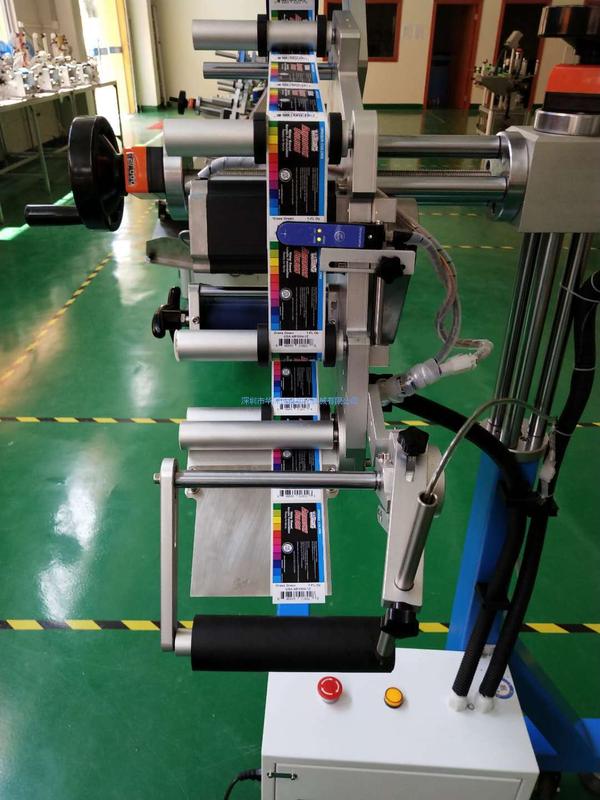

1. Product images

?

?

two, Basic Uses

It can be matched with the workshop assembly line to label the upper surface and side of the products passing through, realizing online labeling. If it is matched with a printer, labeling and coding of the objects passing through can be completed in one step.

threeScope of application

inApplicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

inApplicable products: It can be matched with pillow packaging machines, automatic assembly lines, printing machines, etc. to realize online labeling.

inApplication industries: Widely used in packaging, food, toys, daily chemicals, electronics, medicine and other industries.

inApplication examples: labeling before film bag forming, labeling on assembly line, etc.

Four、Working process

? ?Core working principle: The sensor detects the product passing by and sends a signal back to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the position where the product is to be labeled. The product flows through the labeling roller, the label is rolled over, and the attachment of a label is completed;

? ?Operation process: Product feeding (connecting to the assembly line)—>Product conveying—>Product detection (or receiving external signals)—>Labeling—>Relabeling.

five、Technical parameters:The following are the technical parameters of standard models. Other special requirements and functions can be customized.

?

Labeling accuracy: ? ?±1mm (excluding product and label errors); ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

? Labeling speed: ? 40~120 pieces/minute (depending on product size); ? ? ? ? ? ? ? ? ? ? ? ?

? Applicable product size:No requirement (depends on the conveying parameters of the pipeline

? Applicable label size:length(mm):6mm~250mm ? ?Width (base paper width/mm):6mm~130mm

Machine size: ? ?about1100mm×700mm×1000mm(long× width × height);

? Applicable power supply: ? ?220V/50HZ;

? Machine weight: ? ?about70Kg。

? Applicable label inner diameter:?76mm ? Applicable label outer diameter:??320mm

?

?

?

six、Functional features

inThe matching is simple and can be directly installed on the assembly line and packaging machine, with independent control or linkage control to achieve automatic labeling and unmanned labeling production;

inFlexible application, with different labeling mechanisms, it can be used to label flat and uneven surfaces;

inEasy to adjust, the adjustment structure adopts a single rod structure, the header canx/y/zSix degrees of freedom are flexibly adjustable to flexibly match different production lines;

inHigh labeling accuracy, the label belt bypass correction mechanism prevents the label from deviating, the subdivided stepper motor drives the label output, and the front and rear positions of the label are accurate;

inIntelligent control, automatic photoelectric tracking, with the functions of labeling everything, automatic correction without label and automatic label detection to prevent missing labels and label waste;

inTouch screen operation interface, with full Chinese annotations and complete fault prompt function, various parameters can be adjusted simply and quickly, and the operation is convenient;

inHigh stability, using PanasonicPLC+Panasonic touch screen+Subdivision stepper motor+Fiber optic sensor electronic control system control, precise control, support long-term work;

inOptional functions:

①Hot coding/Coding function;

②Mobile bracket;

③Other functions (customized according to customer requirements).